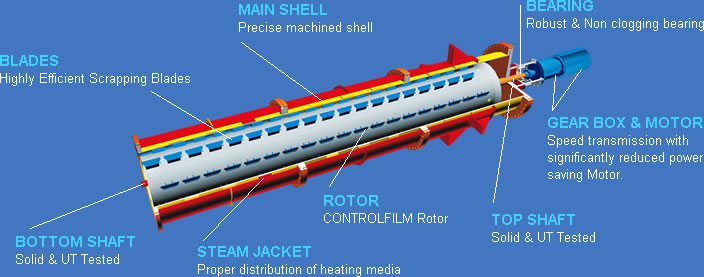

Agitated Thin Film Evaporator

We recommend the DRY CONTROLFILM ROTOR:

Designed for product recovery and other severe service applications such as yours, This drying technology arises from over years experience in soap plant glycerine and inorganic salt recovery. We have optimized the dryer technology for glycerine recovery as well as inorganic salts.

We have special precision designed centrifugally balanced blade design that has higher efficiency compared with other types of dryers. The balance and weighting cause the blade to ride truer and quieter on the film and give higher product quality due to heavily reducing entrainment. The advanced wipers geometry reduce splashing to a minimum, which means less wet salt gets into rotor blade slots. This wet salt causes build up which shuts operations down. In fact the time between required wash cycles are at least three to four times as long as previously experienced. The balanced design means less wear, and less jamming or lockup of blades. The design lifetime is proving to be much longer than previous of wipers due to special mechanical design.

The discharge system has also been enhanced in recent years and can be discussed personally. It is proprietary but not necessarily confidential. Instead of providing any valves to discharge system we recommend maximum up time or directly trolley to removes the bottom products.

How ATFD work:

Wet product in form of slurry (range from 30 to 50 % w/w) fed through the inlet nozzle is conveyed steadily by the rotor blades along the heated dryer wall in a thin film (With the help of steam or Hot Oil or any heating media), normally several millimeters thick, preventing buildup and continuously exposing every particle of the product to the heated surface. Vapors pass counter currently to the product flow and exit the dryer through the feed nozzle, as configured above. Moisture levels from a few tenths of a percent up to 5%+ can be achieved. Residence time is typically controlled as per requirement.

Our thin-film dryers are widely used throughout the process industries to convert liquids, slurries, and pastes to free-flowing solids in continuous, single pass operation.

Our Thin-film Dryers have a short residence time and are very effective in processing heat sensitive products, due to low “hold-up” and self-cleaning heating surfaces.

Salient Features:

- Flexible through exchangeable rotor elements

- Continuous, fully enclosed processing

- Short residence time

- Low residual volatile in final powder

- Superior mixing efficiency

- Self-cleaning of heating surface

- Low energy consumption

- Minimal product hold-up

- High Reliability

- Low Maintenance

Self-Cleaning and Robust Thin Film Technologies