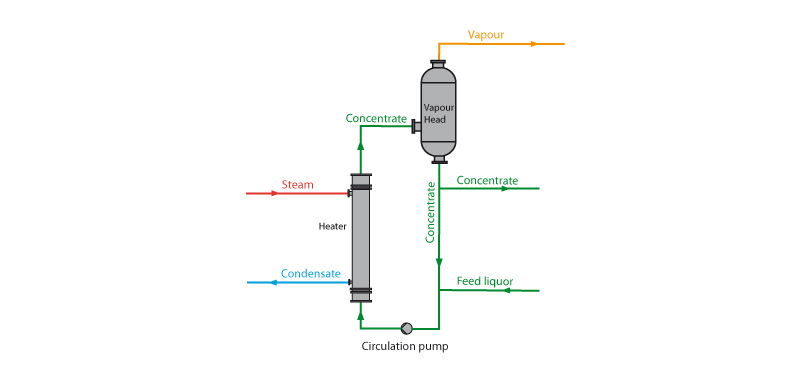

Forced Circulation Evaporator

Circulation evaporators are a type of evaporating unit designed to separate mixtures unable to be evaporated by a conventional evaporating unit. Circulation evaporation incorporates the use of both heat exchangers and flash separation units in conjunction with circulation of the solvent in order to remove liquid mixtures without conventional boiling.

These type of evaporators some mechanical device are fitted to circulate the contents heating in it. For example an evaporating pan in which the materials is agitated by a stirring rod or by a mechanical propeller.

The liquid is circulated by means of a pump and as it is under pressure in the tubes the boiling point is raised and no boling take places. And it enters the body of the evaporator.

The liquid film moves down the tubes by gravity force. Heat applied through the tube wall effects boiling-off the light fraction from the film. The picture shows a co-current operating evaporator with vapour and liquid leaving the bottom of the evaporator into the separator vessel.

Features

- In forced circulation evaporator there is a rapid liquid movement due to high heat transfer coefficient.

- Salting, scaling and fouling are not possible due to forced circulation.

- Suitable for thermolabile substances because of rapid evaporation.

- Suitable for the viscous preparation because pumping mechanism is used.

Applications

- Chemical Industry

- Effluent Treatment Plants

- Polymers Industry

- Food products

- Pharmaceuticals